Labkotec Sensor Systems

Labkotec Sensor Systems Labkotec Separator Alarm System – Protecting Our Environment

Labkotec alarm devices will satisfy the demands in terms of many standards and regulations.

• Designed to comply EN 858-1&2 and PPG3 norms

• Warns of excessive levels of oil, sludge & liquids

• Prevents pollution incidents (spills, leakage)

• Fail-safe & fault monitoring systems in built

• Indicates when separator needs emptying, reducing waste management cost

• Remote monitoring capability

• Sensors for various applications

• No moving parts, Easy installation, ATEX approved

Grease Interceptor Monitoring Devices

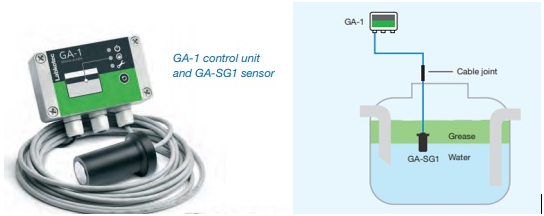

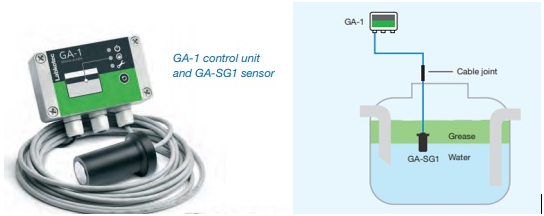

GA-1 Grease Interceptor Monitoring Devices

The GA-1 is designed to help businesses control both their expenditure on unnecessary pumping charges and prevent harmful and costly sanitary sewer discharges from interceptors. This is accomplished by providing an active cost effective monitoring solution.

GA-2 Grease Interceptor Monitoring Devices

The GA-2 builds upon the GA-1 through the inclusion of an additional sensor, the GA-HLL1, which monitors the water level and indicates the controller that the water table has risen within the unit, an indication of a blockage in the discharge line of the interceptor.

Oil Separator Alarms

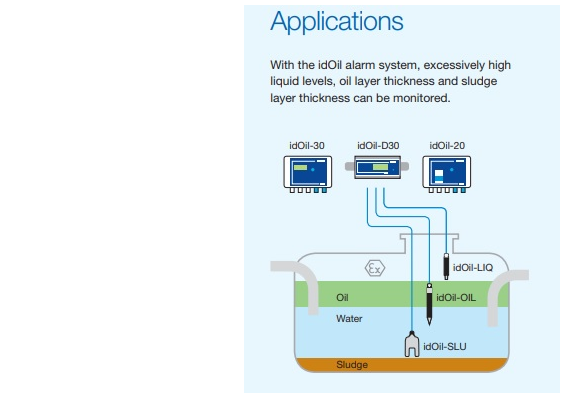

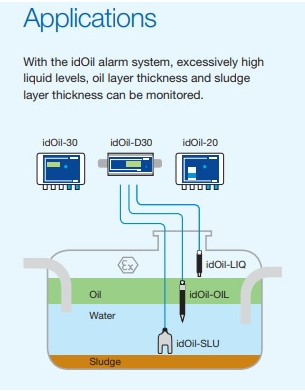

idOil®-20 Oil Separator Monitoring System

The idOil-20 is an easy to use oil separator alarm control unit that offers all necessary basic features. Up to three different types of idOil sensors can be connected polarity-free, and they are identified automatically with a one-touch commissioning feature.

idOil-30 Oil Separator Monitoring System

Up to three idOil sensors of any type can be connected polarity-free, and they are identified automatically with a one-touch commissioning feature. The idOil-30 offers extremely easy commissioning, flexible configuration locally via WLAN, as well as alarm logging.

idOil-D30 Oil Separator Monitoring System

The idOil-D30 has the same features as the idOil-30, but is smaller in size, and can be mounted in an electrical cabinet on DIN rails.

Applications

Labkotec Digital Sensors

idOil-LIQ high liquid level sensor

Utilizing vibration the LIQ sensor indicates when the liquid level in the oil separator rises excessively such as in an outlet blockage situation.

![]()

idOil-OIL oil sensor

Utilizing conduction the OIL sensor detects oil and indicates when the separator’s oil storage is full.

![]()

idOil-SLU sludge sensor

Utilizing ultrasonic the SLU sensor monitors the sludge layer in the oil separator and indicates when the sludge layer has reached its maximum level

GA-SG1 grease sensor

The GA-SG1 grease sensor monitors the grease layer within the separator and will alarm the unit that the interceptor is at a predetermined capacity.

GA-HLL1 high liquid level sensor

The GA-HLL1 high liquid level sensor will alert the unit upon the water level reaching a predetermined height thus indicating that the interceptor has a blockage.

Labkotec Separator Alarm System – Protecting Our Environment

Today, in all construction work, greater attention is being paid to protecting the environment, than ever before. Oil spills into sewers and ground leaks are controlled better than they used to be, thanks to the increasing use of separator systems. Oil separator systems now have a vital part in preventing environmental damage. Similarly, grease needs to be separated from sewage water with grease interceptors.

Typical applications for the grease interceptor systems are restaurants, grocery stores, and high rise buildings and other places where risk of grease discharge into the sanitary sewer line could compromise operating expenditure and procedure.

Typical applications for the oil separator systems are petrol stations, airports, parking areas, highways and other places where the risk of an oil spill onto the ground is present. The best safeguard against environmental damage is of course to use the separator system properly and service it periodically. Total reliability in the operation of the separator system can only be achieved when monitoring systems are installed. Therefore it is possible to guarantee correct functioning of the separator year after year.

Labkotec, with more than 50 years of experience in the industry, is a leading measurement equipment manufacturer and related services provider for various industrial applications. Their mission is to provide measurement solutions which enhance our customers’ business and help them to protect the environment and people.

Labkotec offers the widest range of monitoring devices on the market for oil separators and grease interceptors. Separator monitoring devices are extremely important for the efficient operation of industrial kitchens and restaurants, retail stores and fast-food outlets, as well as industrial installations and garages, car parks, service stations and car washes, airports, motorways, and transport routes near groundwater reserves. The monitoring devices are used to indicate when oil, grease and sand separators need to be emptied.

Oil Separator Alarm Models and Applications

&

Grease Interceptor Monitoring Devices

The idOil-20 is an easy to use oil separator alarm control unit that offers all necessary basic features. Up to three different types of idOil sensors can be connected polarity-free, and they are identified automatically with a one-touch commissioning feature. Up to three idOil sensors of any type can be connected polarity-free, and they are identified automatically with a one-touch commissioning feature. The idOil-30 offers extremely easy commissioning, flexible configuration locally via WLAN, as well as alarm logging. The idOil-D30 has the same features as the idOil-30, but is smaller in size, and can be mounted in an electrical cabinet on DIN rails. The GA-1 is designed to help businesses control both their expenditure on unnecessary pumping charges and prevent harmful and costly sanitary sewer discharges from interceptors. This is accomplished by providing an active cost effective monitoring solution. The GA-2 builds upon the GA-1 through the inclusion of an additional sensor, the GA-HLL1, which monitors the water level and indicates the controller that the water table has risen within the unit, an indication of a blockage in the discharge line of the interceptor. Digital Sensors Utilizing vibration the LIQ sensor indicates when the liquid level in the oil separator rises excessively such as in an outlet blockage situation. Utilizing conduction the OIL sensor detects oil and indicates when the separator’s oil storage is full. Utilizing ultrasonic the SLU sensor monitors the sludge layer in the oil separator and indicates when the sludge layer has reached its maximum level The GA-SG1 grease sensor monitors the grease layer within the separator and will alarm the unit that the interceptor is at a predetermined capacity. The GA-HLL1 high liquid level sensor will alert the unit upon the water level reaching a predetermined height thus indicating that the interceptor has a blockage. Labkotec offers a wide range of oil, sand and grease separator alarm systems. Special attention to the design of various models has improved reliability and performance, which benefits the world’s environment.